| FDM 3D Printers: Revolutionizing Manufacturing and Prototyping |

|

|

|

อ้างอิง

อ่าน 41 ครั้ง / ตอบ 0 ครั้ง

|

tiptoe

|

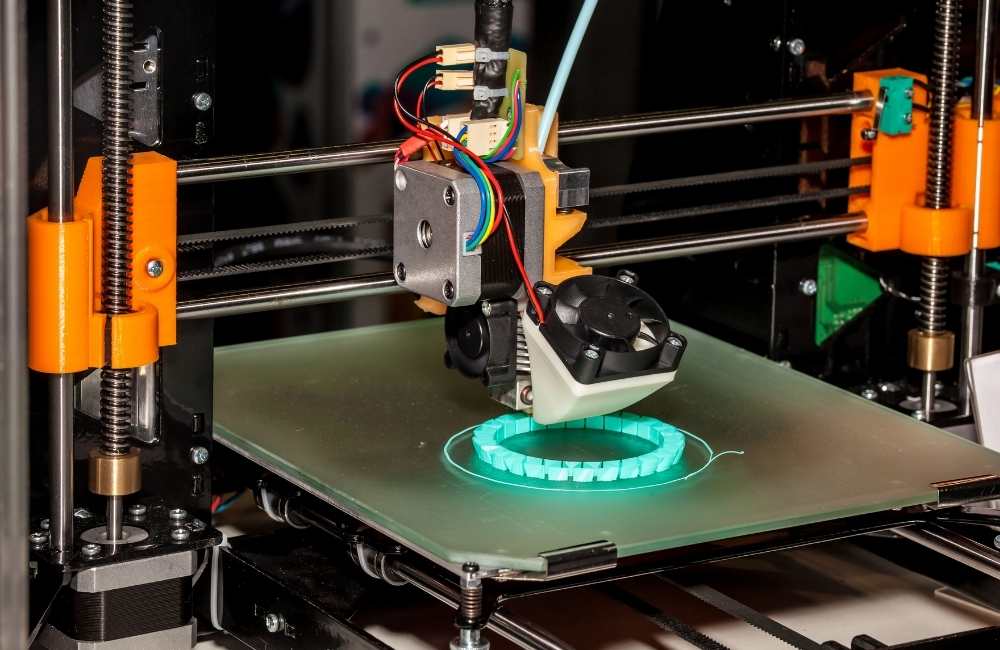

FDM 3D Printers: Revolutionizing Manufacturing and Prototyping

Fused Deposition Modeling (FDM) 3D printing technology has rapidly emerged as one of the most popular and accessible forms of additive manufacturing. Since its invention in the 1980s, FDM has continued to evolve and make a significant impact on industries ranging from engineering and automotive to healthcare and consumer goods. This article explores FDM 3D printers technology.

Key Benefits of FDM 3D Printing

FDM 3D printing offers a wide range of advantages, making it a preferred choice for both professionals and hobbyists.

Cost-Effective

FDM printers are relatively inexpensive compared to other 3D printing technologies like SLA (Stereolithography) or SLS (Selective Laser Sintering). This makes them accessible to a broader range of users, from home enthusiasts to small businesses. Additionally, the filament materials used in FDM printing, such as PLA, ABS, and PETG, are affordable and widely available.

Wide Range of Materials

FDM technology supports a variety of thermoplastic materials, including PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), PETG (Polyethylene Terephthalate Glycol), TPU (Thermoplastic Polyurethane), and many others. Each material offers different properties such as flexibility, durability, and heat resistance, allowing users to choose the best material for their specific application.

Strength and Durability

FDM-printed parts are often strong and durable, making them suitable for functional prototypes and end-use products. While the strength can vary based on the material and print settings, many FDM materials offer mechanical properties similar to traditionally manufactured parts, making them useful for real-world applications.

|

| |

tiptoe [172.69.166.xxx] เมื่อ 12/11/2024 23:02

|